China Pressure Transmitter Suppliers

Pressure Transmitter is a device that converts pressure into a pneumatic signal or an electric signal for control and remote transmission. Pressure Sensor can convert the physical pressure parameters such as gas and liquid felt by the load cell sensor into a standard electrical signal (such as 4~20mADC, etc.), to supply secondary instruments such as indicating alarms, recorders, regulators, etc. for measurement and indication and process regulation.

Pressure transmitters are used in various industrial automatic control environments, involving water conservancy and hydropower, railway transportation, intelligent buildings, production automatic control, aerospace, military industry, petrochemical, oil wells, electric power, ships, machine tools, pipelines and many other industries.

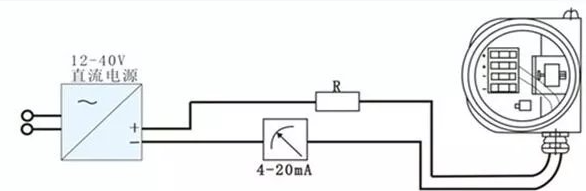

There are two types of pressure transmitters: electric and pneumatic. The uniform output signal of the electric type is a direct current signal such as 0-10mA, 4-20mA or 1-5V. The unified output signal of the pneumatic type is the gas pressure of 20-100Pa.

Pressure transmitters can be divided into force (torque) balance type, capacitive type, inductive type, strain type and frequency type according to different conversion principles.

Our advantageous products are mainly compact pressure transmitters, pressure transmitters with display, differential pressure transmitters, wind pressure transmitters, etc.

The main advantage

1. The pressure transmitter has the characteristics of reliable operation and stable performance

2. Dedicated V/I integrated circuit, less peripheral components, high reliability, simple and easy maintenance, small size, light weight, and extremely convenient installation and debugging;

3. Aluminum alloy die-casting shell, three-terminal isolation, electrostatic spray protection layer, durable;

4. 4-20mA DC two-wire signal transmission, strong anti-interference ability and long transmission distance;

5. LED, LCD, and pointer three kinds of indicator heads, the on-site reading is very convenient. Can be used to measure viscous, crystalline and corrosive media;

6. High accuracy and high stability. In addition to the imported original sensor that has been corrected by laser, the comprehensive temperature drift and nonlinearity of the whole machine within the operating temperature range are finely compensated.